Welcome to our website!

Contact Us: +86-15981997511 elsie@lijiacoating.com

Contact Us: +86-19396498242 info@lijiacoating.com

| Availability: | |

|---|---|

HA-3000+LA201

The user interface is a touchscreen, and the system architecture adopts a fully closed-loop automatic control structure. All gases are managed by American-imported pressure sensors and Japanese-imported regulating valves, enabling real-time pressure monitoring and automatic adjustment to the required process values.

It uses propane as fuel and air as the combustion-supporting agent—currently the safest combustion mode for gas-powered systems on the market.

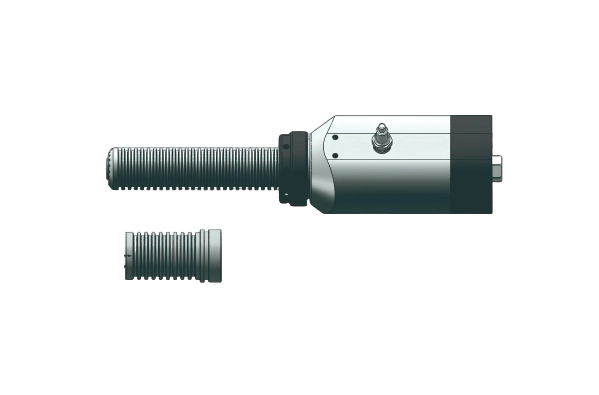

The spray gun is designed based on rocket engine principles, achieving a flame velocity of over 2000m/s, high output power, and stepless adjustability.

The spray gun adopts axial center powder feeding, an innovative injection method that ensures optimal powder melting and uniform distribution in the flame, thereby enhancing coverage efficiency and coating quality.

The system supports storing and recalling process formulas, allowing users to add, modify, and save parameters.

The fuel system features a fully closed-loop design, modular setup, and high-performance PLC control, ensuring safe and simple operation.

The coating has high bond strength and a low porosity of ≤1%, reaching international advanced levels. The system also boasts high spraying efficiency, capable of handling up to 10KG of powder per hour.

Project | Parameter |

Flame temperature | 1500℃ |

Powder particle velocity | 700-1100m/s |

Porosity | ≤1% |

Coating bonding strength | ≥70Mpa(WC) |

Coating hardness | HV1100-1500 |

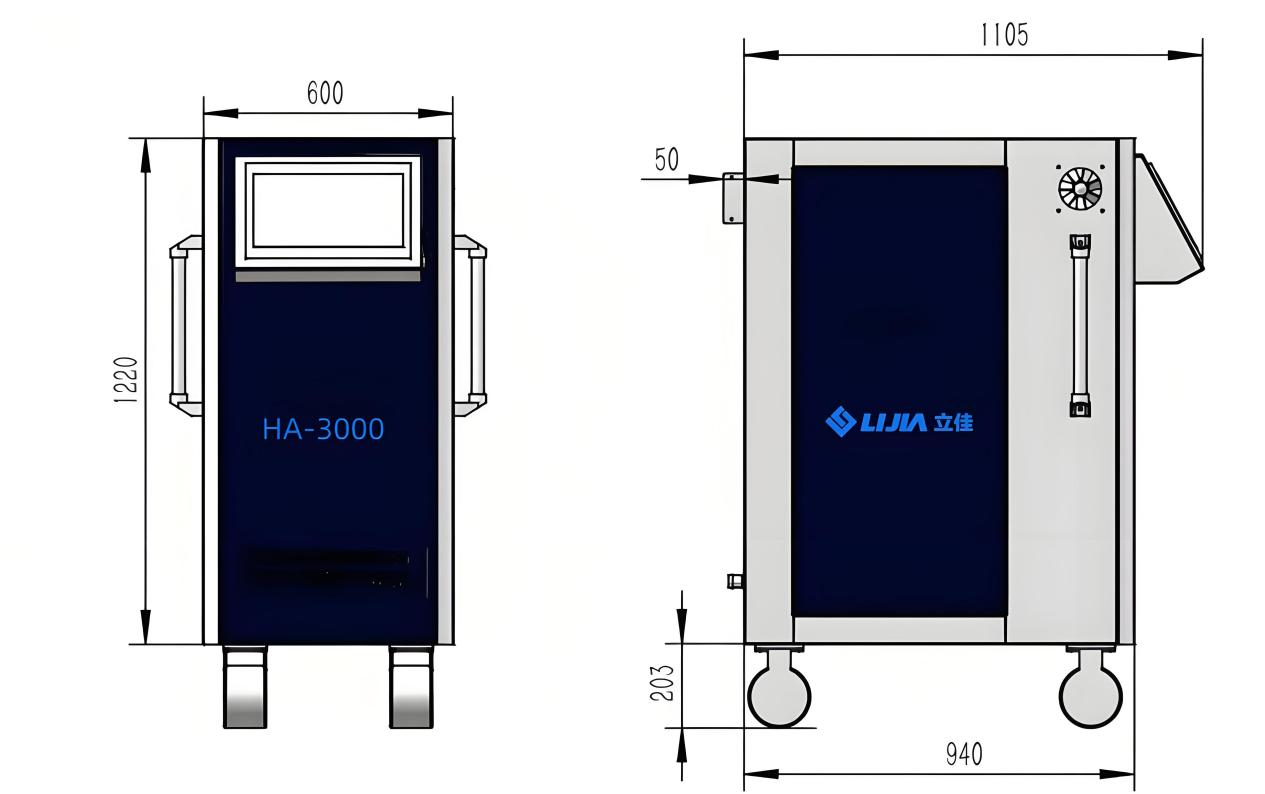

HA-3000 Supersonic Flame Spraying Control Cabinet

Equipped with imported core components, a fully closed-loop system, and high-performance PLC control from Mitsubishi of Japan. l

Features world-renowned brand pressure sensors, solenoid valves, and top-notch quality. l

Operated via touch screen, intelligent and automated in operation.

With one-click operation, automation and real-time detection of the spraying process can be achieved. Multiple alarms can promptly respond to system malfunctions.

Project | Parameter |

Input power supply | AC220/2P/50Hz±5% |

Input power | 15kw |

Program control | Full closed-loop PLC control |

Interface control | 15 inch touch screen |

Flow control | Mass flow controller+electrical pressure regulating valve |

Propane pressure | 1.1Mpa |

Air pressure | 1.2Mpa |

Carrier gas pressure | 1.1Mpa |

Propane flow rate | 0~35kg/h |

Air flow rate | 300-600m³ |

Carrier gas flow rate | 0~100L/min |

Origin of accessories | USA, Japan,Italy |

Size/Weight | 1100*750*1360mm,193kg |

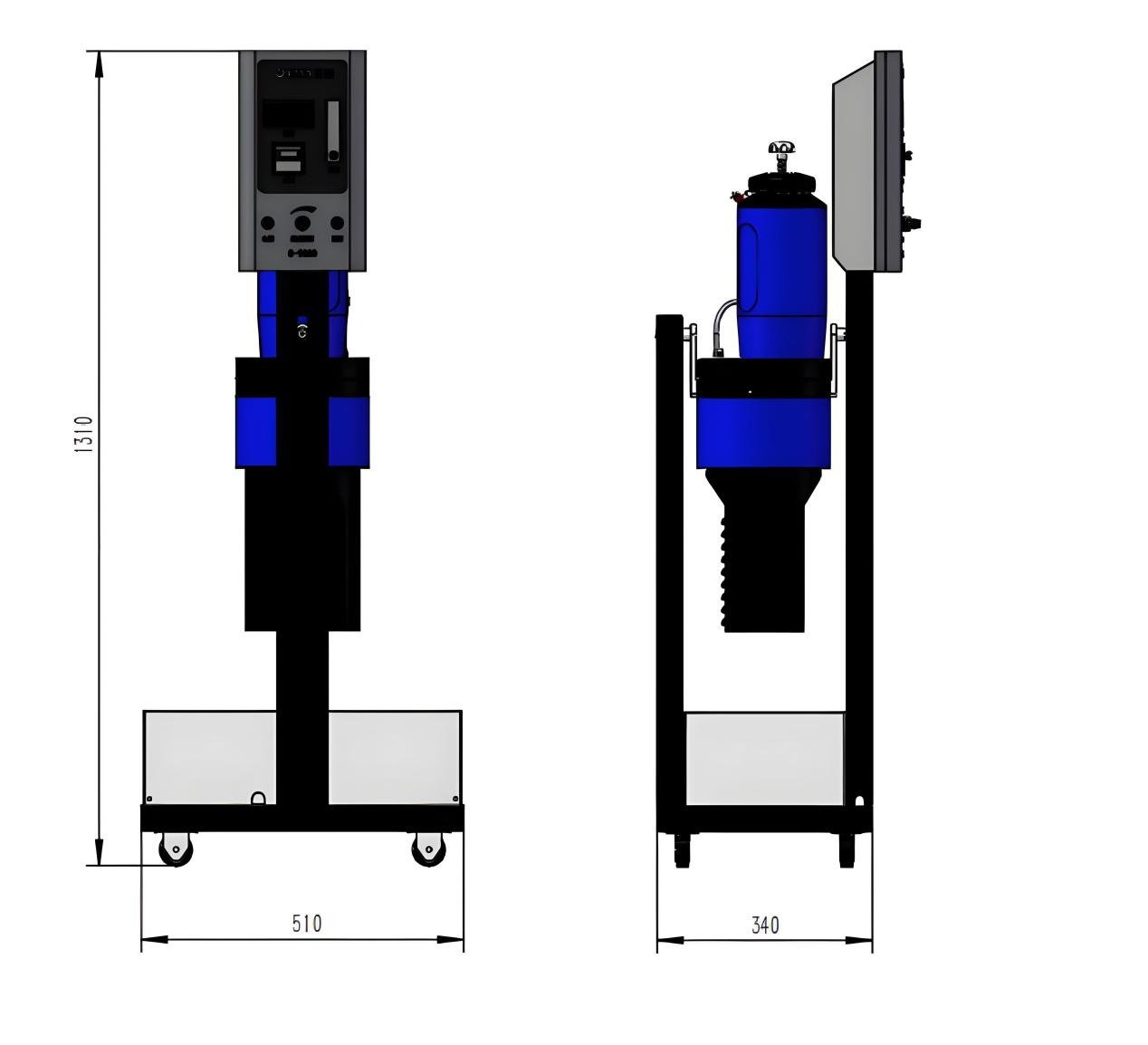

C-1100 base 280mm supersonic flame spraying powder feeder

The powder dispenser is a high-accuracy powder conveying device with turntable scraper discharge, and the powder discharge is even.

Employing a small flow rate of nitrogen or argon as the powder conveying gas, the powder arrives at the powder outlet along with the rotation of the bottom powder conveying tray and enters the spray gun together with the said gas. Compared with traditional medium and high pressure powder dispensers, it consumes less gas.

It covers a wide range of powder particle sizes.

Adopt the globally latest inclined structure, which facilitates powder cleaning. It only takes 3 seconds to flip the barrel and pour out the powder.

Project | Parameter |

Input power supply | AC220V/2P/50Hz±5% |

Input power | 0.5kw |

Powder delivery method | Planetary turntable |

Powder cleaning method | Barrel body flip type |

Powder cylinder mode | Monotube |

Self cleaning function | Yes |

Volume of powder storage cylinder | 3L |

Powder feeding gas | Nitrogen or argon |

Powder feeding pressure | 0.5-1.2Mpa |

Carrier gas flow rate | 0~15L/min |

Powder feeding speed | 0~350g/min |

Powder feeding accuracy | ±1% |

Powder size | 5-150μm |

Size/Weight | 520*470*1260mm, 55kg/pcs |

Aerospace: In the aerospace sector, supersonic spraying technology is used to strengthen and repair the surfaces of critical components like engine compressor blades and bearing sleeves. It enhances wear resistance, corrosion resistance, extends service life, and is also suitable for rapid repair and remanufacturing projects.

Automotive Manufacturing: This technology can strengthen and repair the surfaces of automotive parts (e.g., those in engines and transmission systems), improving their service life and performance.

Electronic Equipment: It is applied to protect and decorate the surfaces of electronic components. For instance, conductive coatings on circuit boards boost electrical conductivity and stability, while coatings on mobile phone casings enhance appearance quality and durability.

Iron and Steel Metallurgy: Supersonic spraying technology improves the high-temperature wear resistance of components such as furnace rolls and immersion rolls, prolonging their service life and reducing costs.

Petrochemical Industry: It strengthens the surface protection of equipment like pistons and pipelines, enhancing their reliability and service life.

Paper Industry: The technology is used for surface treatment of working rolls, increasing their service life and production efficiency.

Biomedical Field: It is applied to the surface treatment of medical devices. For example, antibacterial and anti-corrosion coatings on surgical instruments improve safety and hygiene, while coatings on artificial joints enhance durability and comfort.

Operation: Press this button when operating conditions are met— the button will turn green, and the system will start running. After successful ignition, air pressure, Gas 1 pressure, Gas 2 pressure, and carrier gas flow will gradually rise to the set values. Press the button again, and it will turn light blue and display "Halt": at this point, gas and carrier gas supply will stop, while air continues to flow to cool the barrel. The spray gun will stop automatically once the temperature drops. To stop air output immediately, press the Reset button.

Ignition: If ignition fails during the process, click the Ignition button to retry.

Powder Feeding: After the flame stabilizes, click the Powder Feeding button to start spraying.

Reset: It has two functions. ① As mentioned in the Operation section (to stop air output immediately). ② When the equipment shuts down due to an alarm, troubleshoot first, then press the Reset button to clear the alarm signal—only then can the system run again.