Welcome to our website!

Contact Us: +86-15981997511 elsie@lijiacoating.com

Contact Us: +86-19396498242 info@lijiacoating.com

HA-3000+LA3

The HA-3000 Supersonic Flame Spray System is an innovative type of HVAF (High Velocity Air-Fuel) technology. It creates high-speed airflow by igniting compressed air and propane fuel, heating the powder to over 700m/s, and accelerating it to impact the substrate. This process forms a coating with very low oxygen content and extremely high density. The spraying process has minimal thermal degradation on the spray materials, resulting in coatings that exhibit excellent wear resistance and corrosion resistance.

Our company's engineers developed the HA-3000 spraying system through the introduction, absorption, and digestion of international advanced equipment and technologies. The control panel of the equipment operates entirely via touch screen, featuring internationally leading process settings, spray monitoring, and other functional modules. It includes all necessary operations, information displays, and fault alarms, making it highly user-friendly, simple to use, and stable in quality.

1.The user interface is a touchscreen, and the system architecture employs a fully closed-loop automatic control structure. All gases are managed by American-imported pressure sensors and Japanese-imported regulating valves, enabling real-time pressure monitoring and automatic adjustment to the desired process values;

2.Propane is used as fuel with air as the combustion-supporting agent, representing the safest combustion mode in the current market for gas-powered systems;

3.The design of the spray gun is based on the principles of rocket engines, achieving flame velocities exceeding 2000m/s, high output power, and stepless adjustability;

4.The spray gun utilizes axial center powder feeding, an innovative injection method that ensures optimal powder melting and uniform distribution throughout the flame, enhancing coverage efficiency and coating quality;

5.The system features the ability to store and recall process formulas, allowing for parameter addition, modification, and saving;

6.The fuel system adopts a fully closed-loop design with a modular approach and high-performance PLC control, ensuring safe and straightforward operation;

7.The coating demonstrates high bond strength with a low porosity rate of ≤1%, reaching an international advanced level. The system boasts high spraying efficiency, capable of delivering up to 30KG of powder per hour;

8.It is compatible with the LA2 series of spray guns for enhanced functionality.

The HA-3000 supersonic flame spray system can be matched with LA2 or LA3 propane air supersonic flame spray guns

The spray gun is rated as the most stable and reliable universal air supersonic flame spray gun by users around the world, and the spray gun only uses propane or propylene as fuel when used, which is highly safe.

Customers can also choose to add hydrogen for use

The main structure of the LA2 spray gun is the way in which the combustion chamber is connected to the first-stage combustion nozzle, part of the air is used to support combustion, and part is used to cool the gun body and directly discharge it out of the gun.

The main structure of the LA3 spray gun is the way in which the combustion chamber is connected to the 2-stage combustion nozzle, part of the air is used to support combustion, and part of it is used to cool the front end of the barrel, and the cooled air is then folded back into the barrel, and secondary propane is added to mix with air to burn to produce more heat energy.

After combustion, the flame gas instantly expands several times, and the inside of the gun body pushes the powder particles stronger, so that the particles fly faster, and the coating presents excellent characteristics, such as low porosity and higher coating hardness.

LA2 supersonic flame spray gun technical specifications(optional Configuration)

Project | Parameter |

Flame speed | ≥2000m/s |

Flame temperature | 1600℃ |

Spraying speed | Max 20kg(WC) |

Sedimentation rate | 35%-65% |

Powder particle velocity | 850-1100m/s |

Porosity | ≤1% |

Coating bonding strength | ≥70Mpa(WC) |

Coating hardness | |

Powder particle size | -30+5μm,-25+5μm,-45+15μm,-38+10μm |

Size/Weight | Φ93*380mm,6kg |

LA3 Supersonic flame spray gun technical specifications (standard configuration)

Project | Parameter |

Flame speed | ≥2000m/s |

Flame temperature | 1700℃ |

Spraying speed | Max 30kg(WC) |

Sedimentation rate | 35%-62% |

Powder particle velocity | 850-1100m/s |

Porosity | ≤0.5% |

Coating bonding strength | ≥70Mpa(WC) |

Coating hardness | HV300 1100~1650 |

Powder particle size | -45+15μm,-30+5μm,-25+5μm |

Size/Weight | Φ120*470mm,8kg |

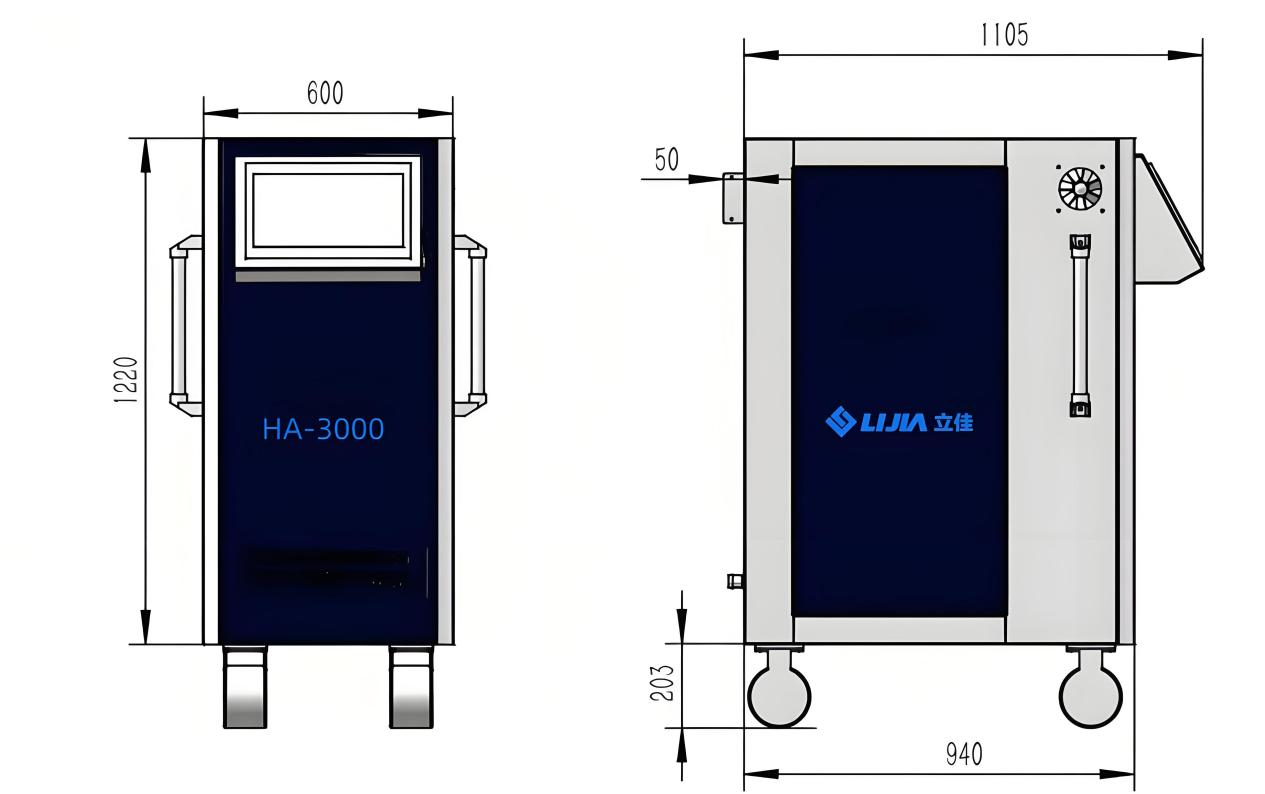

HA-3000 Supersonic Flame Spraying Control Cabinet

Equipped with imported core components, a fully closed-loop system, and high-performance PLC control from Mitsubishi of Japan. l

Features world-renowned brand pressure sensors, solenoid valves, and top-notch quality. l

Operated via touch screen, intelligent and automated in operation.

With one-click operation, automation and real-time detection of the spraying process can be achieved. Multiple alarms can promptly respond to system malfunctions.

Project | Parameter |

Input power supply | AC220/2P/50Hz±5% |

Input power | 15kw |

Program control | Full closed-loop PLC control |

Interface control | 15 inch touch screen |

Flow control | Mass flow controller+electrical pressure regulating valve |

Propane pressure | 1.1Mpa |

Air pressure | 1.2Mpa |

Carrier gas pressure | 1.1Mpa |

Propane flow rate | 0~35kg/h |

Air flow rate | 300-600m³ |

Carrier gas flow rate | 0~100L/min |

Origin of accessories | USA, Japan,Italy |

Size/Weight | 1100*750*1360mm,193kg |

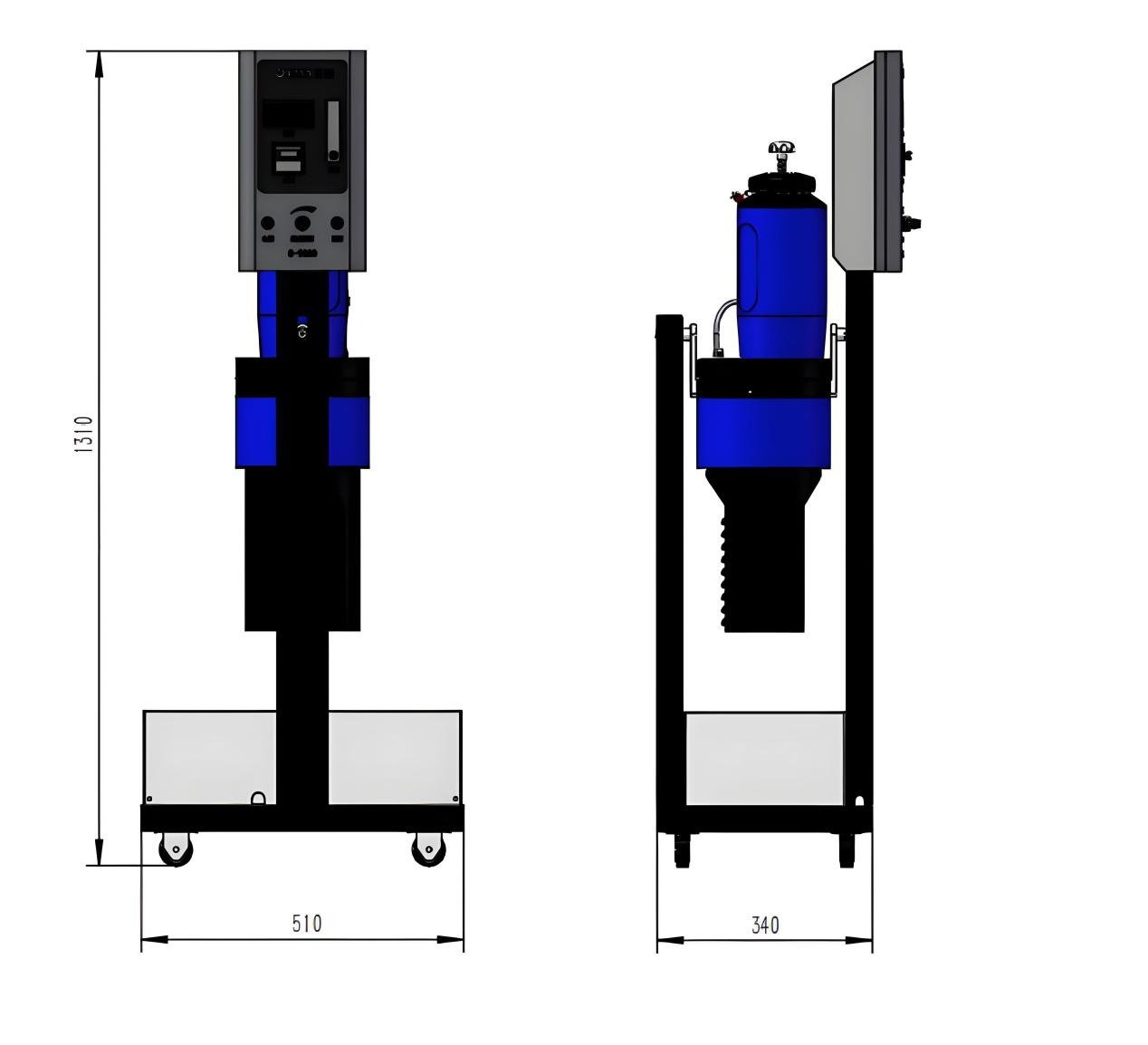

C-1100 base 280mm supersonic flame spraying powder feeder

The powder dispenser is a high-accuracy powder conveying device with turntable scraper discharge, and the powder discharge is even.

Employing a small flow rate of nitrogen or argon as the powder conveying gas, the powder arrives at the powder outlet along with the rotation of the bottom powder conveying tray and enters the spray gun together with the said gas. Compared with traditional medium and high pressure powder dispensers, it consumes less gas.

It covers a wide range of powder particle sizes.

Adopt the globally latest inclined structure, which facilitates powder cleaning. It only takes 3 seconds to flip the barrel and pour out the powder.

Project | Parameter |

Input power supply | AC220V/2P/50Hz±5% |

Input power | 0.5kw |

Powder delivery method | Planetary turntable |

Powder cleaning method | Barrel body flip type |

Powder cylinder mode | Monotube |

Self cleaning function | Yes |

Volume of powder storage cylinder | 3L |

Powder feeding gas | Nitrogen or argon |

Powder feeding pressure | 0.5-1.2Mpa |

Carrier gas flow rate | 0~15L/min |

Powder feeding speed | 0~350g/min |

Powder feeding accuracy | ±1% |

Powder size | 5-150μm |

Size/Weight | 520*470*1260mm, 55kg/pcs |

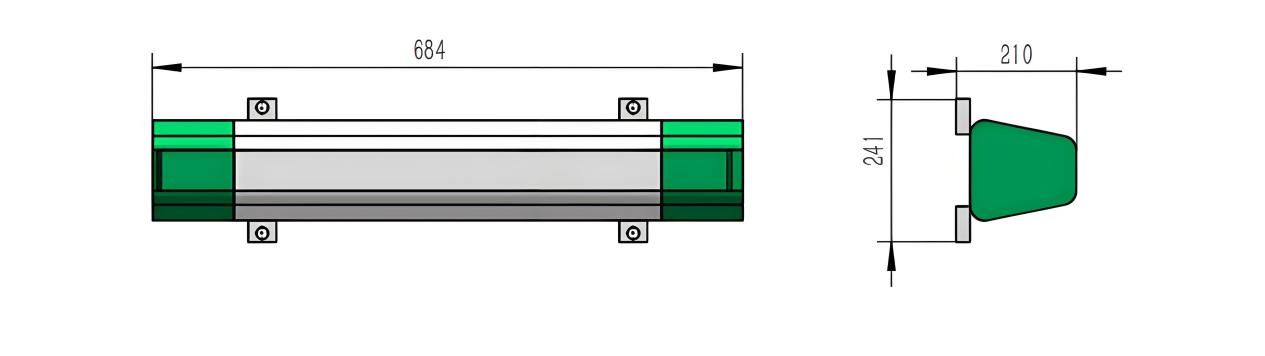

Zimmer Z50P propane gas supply system

Vaporizers are more efficient than water bath vaporizers and are compact for easy installation.

Project | Parameter |

Input power supply | AC220/2P/50Hz±5% |

Input power | 6.5kw |

Gasification capacity | 50kg/h max |

Design pressure | 250psig-17.2barg |

Test pressure | 375psig-25.9barg |

Dimensional weight | 700*241*260mm,50kg |

1. Aerospace: In the aerospace sector, supersonic spraying technology is utilized for the surface strengthening and repair of critical components like engine compressor blades and bearing sleeves. It can enhance wear resistance, corrosion resistance, and extend the service life. Additionally, it is suitable for rapid repair and remanufacturing projects.

2. Automotive Manufacturing: This technology can be employed for the surface strengthening and repair of automotive parts such as those in the engine and transmission systems, improving their service life and performance.

3. Electronic Equipment: It is used for the surface protection and decoration of electronic components. For example, conductive coatings on circuit boards boost electrical conductivity and stability, while coatings on mobile phone casings enhance the appearance quality and durability.

4. Iron and Steel Metallurgy: Supersonic spraying technology improves the high - temperature wear resistance of components like furnace rolls and immersion rolls, prolonging their service life and reducing costs.

5. Petrochemical Industry: It strengthens the surface protection of equipment such as pistons and pipelines, enhancing their reliability and service life.

6. Paper Industry: The technology is applied to the surface treatment of working rolls, increasing their service life and production efficiency.

7. Biomedical Field: It is used for the surface treatment of medical devices. For example, antibacterial and anti - corrosion coatings on surgical instruments improve safety and hygiene, and coatings on artificial joints enhance durability and comfort.

1. Operation - Press this button when the operating conditions are met. The button will be displayed in green. The system will commence operation. After successful ignition, the air pressure, gas 1 pressure, gas 2 pressure, and carrier gas flow will gradually ascend to the set value. When pressed again, the button turns light blue and shows the word 'halt'. At this moment, the gas and carrier gas are halted, and the air continues to output to cool the barrel. The gun automatically stops when the temperature drops. If immediate cessation of air output is desired, press the reset button to achieve this.

2.Ignition - During the ignition process, if ignition is unsuccessful, click the ignition button to reignite.

3.Powder feeding - After the flame is stable, click the powder feeding button to commence spraying.

4.Reset - It has two functions. The first function: refer to the operation explanation. The second function: After an alarm occurs and the equipment shuts down, if you want to run it again, you need to press the reset button to clear the alarm signal after troubleshooting. Only then can the system operate again.

Q: Is the installation and commissioning of the equipment intricate? Do you provide on-site installation services?

A: The installation and commissioning of the equipment is not complex. We have provided detailed installation manuals and video tutorials, and our professional technical support team is always available to provide you with online guidance."

Q: If I wish to spray some special material coatings, for instance, ceramic matrix composite coatings, can the equipment handle this task?

A: Our equipment is extremely versatile and adaptable, and is entirely capable of spraying special materials like ceramic matrix composite coatings. On one hand, the equipment has a broad range of parameter adjustments that can precisely match the process parameters according to the characteristics of different materials. On the other hand, we have a professional R&D team that can offer you customized spraying solutions to ensure that the coating quality meets your expectations and satisfies your special needs in high-end manufacturing, aerospace and other fields.

Q: What are the payment terms?

A: We generally accept payment via Telegraphic Transfer (T/T). We can also discuss other payment methods as per your requirements. A certain percentage of the payment may be required as an advance before production, and the balance should be paid before shipment.