Welcome to our website!

Contact Us: +86-15981997511 elsie@lijiacoating.com

Contact Us: +86-19396498242 info@lijiacoating.com

Chromium oxide ceramic powder coating (Cr ₂ O3) is a high-performance functional coating material that plays an important role in many industrial fields due to its multiple excellent characteristics.

In terms of coating hardness, this coating exhibits a strong advantage, with a hardness of up to 950-1350 HV0.3. This high hardness characteristic is the solid foundation for achieving excellent wear resistance, which can effectively resist various friction and wear conditions, greatly extending the service life of coated components. At the same time, it also has the characteristic of low friction coefficient, which can reduce the frictional resistance of components during operation, reduce energy loss, and improve the operating efficiency of equipment.

Chemical stability is another highlight of this coating. It has strong chemical inertness, exhibits good corrosion resistance to most acids and bases, and is insoluble in acids, bases, and alcohol. This excellent corrosion resistance enables the coating to maintain stable performance in various harsh chemical environments, providing reliable protection for the protected substrate and reducing equipment damage and failures caused by chemical corrosion.

In terms of physical performance, Chromium oxide ceramic powder coating also performs outstandingly. It has a high melting point and can maintain the structural stability and performance integrity of the coating at higher temperatures. Moreover, its coefficient of thermal expansion is small, which means that in working conditions with large temperature changes, the coating is less likely to crack or peel off due to thermal expansion and contraction, ensuring the firm bonding between the coating and the substrate. In addition, the coating also has low conductivity and can function in some scenarios that require electrical insulation, avoiding equipment failures or safety hazards caused by conductivity.

From the perspective of the structural quality of the coating, its porosity is less than 2.5%. The low porosity ensures the compactness of the coating, which not only helps to enhance the wear resistance and corrosion resistance of the coating, but also effectively blocks the invasion of external media, further improving the protective effect of the coating on the substrate. This results in the prepared coating exhibiting uniform and dense characteristics, comprehensively possessing excellent properties such as high hardness, wear resistance, and corrosion resistance.

In terms of applicable temperature, this coating can be stably used in environments below 540 ℃, meeting the temperature requirements of many industrial scenarios and providing reliable coating protection for equipment components operating within this temperature range.

In summary, Chromium oxide ceramic powder coating (Cr ₂ O3) has become an ideal coating material for component protection and performance improvement in the industrial field due to its high hardness, wear resistance, low friction, enhanced inertness, acid and alkali resistance, high melting point, low thermal expansion coefficient, low conductivity, and low porosity.

Chromium oxide ceramic powder coating (Cr ₂ O3) has been widely and effectively applied to key components in multiple industrial fields due to its excellent properties such as high hardness, wear resistance, corrosion resistance, and low friction coefficient, providing strong guarantees for the stable operation and extended service life of equipment in various industries.

Printing industry: laser engraving ceramic mesh roller

In the printing industry, laser engraved ceramic mesh rollers are the core components for achieving precise ink transfer and ensuring printing quality. The surface of the mesh roller needs to have extremely high wear resistance to withstand long-term ink grinding and scraper scratching, while maintaining surface accuracy and flatness. The hardness of Chromium oxide ceramic powder coating can reach 950-1350 HV0.3, which can effectively resist the wear of ink particles and the friction of scrapers, greatly extending the service life of the mesh roller. Its low friction coefficient characteristic can reduce the adhesion resistance of ink on the roller surface, ensure the uniformity and stability of ink transmission, and improve the clarity and consistency of printed materials. In addition, the chemical inertness of the coating enables it to withstand the erosion of various inks and solvents during the printing process, avoiding damage to the roller surface due to chemical corrosion and ensuring that the mesh roller maintains a good working condition for a long time.

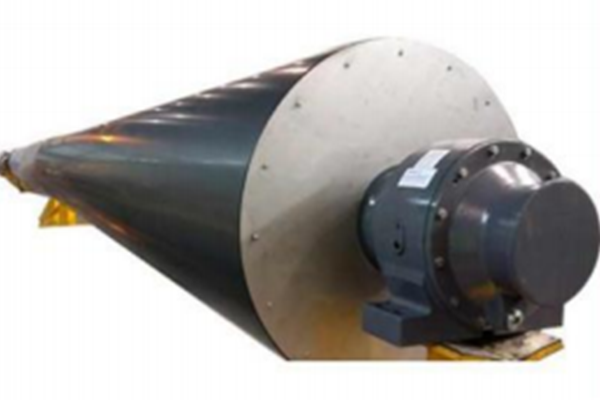

Paper and pulp industry: large rollers

The large rollers in the paper and pulp industry need to come into contact with pulp, moisture, and various chemical additives during the production process. The working environment is complex and requires extremely high wear and corrosion resistance of the rollers. Large rollers bear the tension and friction of paper for a long time, and their surfaces are prone to wear and corrosion. The high hardness and wear resistance of Chromium oxide ceramic powder coating can effectively resist the friction and wear of paper fibers, reducing roller surface wear. Its strong chemical inertness can withstand the erosion of acidic and alkaline substances, bleaching agents and other chemical reagents in pulp, preventing problems such as corrosion and pitting on the roller surface. At the same time, the coating porosity is less than 2.5%, and the dense structure can block the penetration of moisture and chemical media, protect the roller substrate from damage, extend the maintenance cycle and service life of large rollers, and reduce equipment downtime maintenance costs.

Textile industry: hot rollers, wire guides

The hot rollers and wire guides in the textile industry need to withstand high temperatures, fiber friction, and a certain amount of tension during operation. The hot roller needs to maintain structural stability at high temperatures, while the wire guide disc needs to ensure smooth and accurate wire transmission. Chromium oxide ceramic powder coating has a high melting point and is suitable for temperatures below 540 ℃. It can maintain the stability and performance integrity of the coating under the working temperature environment of the hot roller, and will not soften or peel off due to high temperature. Its low thermal expansion coefficient characteristics make the coating less prone to cracking during temperature changes, ensuring the flatness of the surface of the hot roller and guide wire disc. A low coefficient of friction can reduce the frictional resistance between fibers and roller surfaces, as well as the surface of guide discs, lower the breakage rate of silk threads, and ensure the continuity of textile production. In addition, the wear resistance of the coating can resist surface wear caused by long-term friction of fibers, maintain the accuracy of components, and improve the quality of textiles.

In the field of mechanical engineering

Shaft sleeve, seal, wear-resistant ring

The shaft sleeve, seal, and wear-resistant ring in mechanical engineering are key components that ensure the performance of mechanical transmission and sealing. They are subjected to long-term friction, compression, and other working conditions, and have strict requirements for wear resistance and sealing. The high hardness and wear resistance of Chromium oxide ceramic powder coating can significantly enhance the wear resistance of these components, reduce losses caused by friction, and extend their service life. Low friction coefficient can reduce the frictional resistance between components, improve mechanical transmission efficiency, and reduce energy loss. For seals, the density of the coating (porosity<2.5%) can enhance their sealing performance, effectively block the leakage of the medium, and ensure the normal operation of the mechanical system.

Mechanical seal ring, valve seat

Mechanical seal rings and valve seats play a critical sealing role in fluid control systems, requiring resistance to corrosion from fluid media and wear caused by relative motion. The strong chemical inertness of Chromium oxide ceramic powder coating enables it to resist corrosion from various acidic and alkaline media, oil products, etc., ensuring the stability of the sealing ring and valve seat in complex media environments. High hardness and wear resistance can reduce wear between sealing surfaces, ensure the stability of sealing gaps, improve sealing effectiveness, and reduce leakage risks. At the same time, the low friction characteristics of the coating can reduce the friction and wear between the sealing surfaces, prolong the service life of the seals, and reduce the frequency of equipment maintenance.

Hydraulic piston rod, bearing outer ring

Hydraulic piston rods require frequent expansion and contraction during operation, and their surfaces are susceptible to friction and wear from impurities in hydraulic oil. At the same time, it is necessary to prevent hydraulic oil leakage and the invasion of external pollutants. The outer ring of the bearing needs to withstand the pressure and friction of the rolling elements to maintain rotational accuracy. Chromium oxide ceramic powder coating can form a hard and wear-resistant protective layer on the surface of hydraulic piston rods, resisting friction and impurity wear, reducing the wear of piston rods, and ensuring their motion accuracy. The density of the coating can effectively block the penetration of hydraulic oil and the invasion of external moisture and dust, protecting the piston rod substrate. For the outer ring of the bearing, the high hardness and wear resistance of the coating can improve its ability to resist fatigue wear, extend the service life of the bearing, and ensure the smoothness of mechanical rotation.

In the field of chemical engineering and transportation: the inner walls of pipelines for transporting acidic and alkaline media, stirring shafts, and sealing surfaces of reaction vessels

In the field of chemical engineering, the inner walls of pipelines transporting acidic and alkaline media, stirring shafts, and sealing surfaces of reaction vessels are exposed to highly corrosive media for a long time, requiring extremely high corrosion resistance of materials. Chromium oxide ceramic powder coating has extremely strong chemical inertness and is insoluble in acids, bases, and alcohols. It can effectively resist corrosion from various acidic and alkaline media, protecting pipelines, stirring shafts, and reactor substrates from corrosion and damage. After coating the inner wall of the pipeline with this coating, it can reduce the frictional resistance during the medium transportation process, prevent the corrosion and erosion of the pipeline by the medium, extend the service life of the pipeline, and reduce the risk of pipeline leakage. The coating on the surface of the stirring shaft can resist the impact and friction of the medium during the stirring process, ensuring the structural strength and operational stability of the stirring shaft. The coating on the sealing surface of the reaction vessel can maintain good sealing and wear resistance in high temperature, high pressure, and corrosive environments, ensuring the safe and stable operation of the reaction vessel.

Chromium oxide ceramic powder coating (Cr ₂ O3), with its comprehensive and excellent performance, can play an important role in various key components of printing, papermaking, textile, mechanical engineering, chemical and other industries, providing reliable technical support for improving production efficiency, extending equipment life and reducing operating costs in various industries.