Welcome to our website!

Contact Us: +86-15981997511 elsie@lijiacoating.com

Contact Us: +86-19396498242 info@lijiacoating.com

| Availability: | |

|---|---|

Chromium oxide 25% titanium oxide (Cr₂O₃-25% TiO₂) coating powder is prepared through scientific composition ratio and advanced technology, combining the excellent corrosion resistance of chromium oxide with the toughening properties of titanium oxide, forming a high-performance coating material with mechanical properties, protective properties, and process advantages. Its core functional characteristics are as follows:

Optimized mechanical properties: the advantage of balancing hardness and toughness

The hardness of the coating made of this coating powder can reach 900 HV0.3. While maintaining a high hardness to resist daily friction and wear, its outstanding toughness becomes a significant advantage - its toughness is better than that of pure chromium oxide coatings, which is due to the effective improvement of brittle defects in pure chromium oxide coatings by the addition of titanium oxide components. This "hard but not brittle" characteristic makes the coating less prone to cracking and peeling when subjected to impact, vibration, or cold and hot cycles, enabling it to better adapt to dynamic loads under complex working conditions, significantly reducing the risk of component damage caused by coating failure, and extending the service life of the protected substrate.

Excellent protective performance: dense structure with dual protection of wear resistance and corrosion resistance

The coating porosity is less than 2.5%, forming a uniform and dense microstructure, which is not only superior to the compactness of pure chromium oxide coatings, but also becomes the core support for protective performance. The dense coating structure can effectively block the penetration of external dust, moisture, and corrosive media, building a solid physical barrier for the substrate and exhibiting excellent corrosion resistance, which can resist the erosion of various acidic and alkaline environments and industrial media. At the same time, the high density combined with a hardness of 900 HV0.3 gives the coating excellent wear resistance. In scenarios such as component friction and particle erosion, it can significantly reduce surface material loss and maintain the dimensional accuracy and surface smoothness of the components.

Good temperature adaptability: performance stability in medium to high temperature environments

This coating is suitable for temperatures below 500 ℃ and can maintain stable structure and performance under medium to high temperature conditions. Even in environments with temperature fluctuations, the coating has excellent toughness and good thermal stability, making it less prone to internal stress cracking due to thermal expansion and contraction. It can be reliably applied to scenarios such as industrial furnace auxiliary components and medium temperature conveyor rollers that require a certain temperature tolerance, ensuring that the protective effect of the components does not deteriorate during temperature changes.

Unique conductivity and efficient process characteristics

Different from some insulating ceramic coatings, this coating has a certain degree of conductivity, which makes it more suitable for special scenarios that require both wear resistance, corrosion resistance, and conductivity. For example, in certain industrial components that require static elimination or electrical signal transmission, it can meet both protection and functional requirements. In addition, coating powders have higher deposition efficiency, which can form coatings more quickly and uniformly during spray coating and other preparation processes, shorten production cycles, reduce processing costs, and ensure the stability of coating quality, providing convenience for large-scale production.

Chromium oxide 25% titanium oxide (Cr₂O₃-25% TiO₂) coating powder, with optimized mechanical properties, excellent protective performance, good temperature adaptability, and unique process advantages, has demonstrated significant application value in key components of various industries such as hydraulic, textile, and mechanical engineering, providing strong support for the stable operation and extended service life of equipment in various industries.

Hydraulic industry: sealing area between piston rod and pump

In the hydraulic industry, the piston rod is the core moving component of the hydraulic system, which is subjected to high-frequency expansion and contraction movements for a long time. Its surface is susceptible to friction and wear caused by impurities in the hydraulic oil, as well as the impact of hydraulic system pressure. The hardness of the chromium oxide 25% titanium oxide coating reaches 900 HV0.3, which can effectively resist the friction loss of the piston rod during movement. At the same time, its outstanding toughness can buffer the stress caused by hydraulic impact, avoid coating cracking or peeling, and ensure the movement accuracy and sealing performance of the piston rod. The sealing area of the pump requires extremely high sealing and wear resistance. The dense structure of the coating with a porosity<2.5% can effectively block the penetration of hydraulic oil, prevent leakage, and the excellent corrosion resistance can resist the chemical erosion of hydraulic oil, prolong the service life of the pump sealing area, and reduce hydraulic system failures.

Dry battery production: Core shaft

The dry battery core shaft needs to frequently come into contact with the battery material and undergo precise transmission during the production process, with high requirements for surface wear resistance and stability. The high hardness and wear resistance of the chromium oxide 25% titanium oxide coating can reduce the friction loss between the core shaft and the battery material, maintain the dimensional accuracy of the core shaft, and ensure the continuity and stability of battery production. At the same time, the compactness of the coating can prevent corrosive components in the battery material from corroding the core matrix, and a certain level of conductivity can also meet the requirements of electrostatic elimination in specific production processes, improving the reliability of dry battery production.

Textile Industry: Components and Drum shaped Blades

Components in the textile industry, such as guide rollers and stretching rollers, are exposed to fiber friction and a certain temperature environment for a long time. The high toughness and wear resistance of this coating can effectively resist the continuous friction of fibers, avoid scratches or wear on the surface of components, ensure smooth fiber transmission, and reduce the problem of wire breakage caused by component wear. Drum shaped blades need to have sharpness and wear resistance in textile cutting and other processes. The high hardness of the coating can maintain the sharpness of the blade and extend its service life, while the uniform and dense coating can ensure the accuracy and stability of blade cutting and improve the processing quality of textile products.

Compressor and cylinder: compressor screw and cylinder inner wall

The compressor screw bears enormous friction and pressure during high-speed operation. The high hardness and low friction characteristics of the chromium oxide -25% titanium oxide coating can reduce friction losses between screws and between screws and shells, reduce energy consumption, and at the same time, high compressive strength can cope with high-pressure conditions during compressor operation, ensuring the structural stability of screws. The long-term contact friction between the inner wall of the cylinder and the piston can reduce the wear of the inner wall, improve the sealing performance of the cylinder, reduce the risk of gas leakage, and the corrosion resistance can resist the corrosion of impurities that may exist in the compressed gas, extending the maintenance cycle of the cylinder.

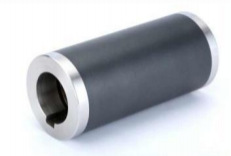

Mechanical engineering: shaft sleeve and wear-resistant ring

The shaft sleeve and wear-resistant ring in mechanical engineering are key components for reducing friction and bearing loads on shaft components. The excellent wear resistance of chromium oxide -25% titanium oxide coating can reduce the friction coefficient between the shaft sleeve and wear-resistant ring and the shaft, reduce energy loss, and improve mechanical transmission efficiency. The high toughness and impact resistance of the coating can buffer the vibration and impact loads during operation, avoiding the failure of the shaft sleeve and wear-resistant ring due to brittle cracking. At the same time, the dense coating structure can prevent impurities in the lubricating oil from entering the friction surface, further enhancing its wear resistance and extending the service life of shaft components.