Welcome to our website!

Contact Us: +86-15981997511 elsie@lijiacoating.com

Contact Us: +86-19396498242 info@lijiacoating.com

| Availability: | |

|---|---|

Chromium oxide -5% silicon dioxide -3% titanium oxide (Cr₂O₃-5% SiO₂-3% TiO₂) powder is a carefully developed high-performance thermal spraying material, specially designed to meet the high requirements for material surface performance under harsh working conditions.

1、 Excellent coating performance

Ultra high hardness: The coating made of this powder can achieve a hardness of 950-1200 HV0.3. This hardness level far exceeds many conventional coating materials, endowing the coating with excellent resistance to abrasive wear. In practical applications, when the coating surface frequently rubs against hard particles, such as the erosion of equipment components by ore in mining machinery, high hardness can effectively resist the cutting and scratching of the coating surface by abrasive particles, greatly reducing the wear rate and extending the service life of the equipment.

Low porosity: A porosity of less than 2.0% results in a dense coating structure. The low porosity effectively prevents corrosive media, such as acid and alkali solutions in chemical production and saltwater in marine environments, from penetrating into the interior of the coating, avoiding coating corrosion failure caused by medium invasion and providing a reliable corrosion-resistant barrier for the coating.

Good medium temperature stability: Suitable for temperatures<540 ℃, within this temperature range, the coating can maintain the stability of its physical and chemical properties. Whether in the medium temperature environment of industrial kilns or on components with thermal cycling such as engine exhaust pipes, the coating will not experience hardness reduction, deformation, or detachment from the substrate due to temperature changes, ensuring long-term stable operation of the equipment under medium temperature conditions.

Excellent comprehensive protection performance: The coating produced is uniform and dense, with high hardness, wear resistance, corrosion resistance and other properties. Its wear resistance and mechanical impact resistance are superior to pure chromium oxide coatings. When facing high-frequency impacts between mechanical components, such as the surface of forging equipment molds, coatings can effectively absorb impact energy, reduce the risk of crack formation, and continuously resist wear with high hardness, achieving comprehensive protection of the substrate.

2、 Unique synergistic effects of ingredients

Chromium oxide (Cr₂O₃): As the main component, chromium oxide itself has good hardness, corrosion resistance, and wear resistance, and is the key to building the basic performance of coatings. It endows the coating with excellent chemical stability, highly resistant to common acidic and alkaline chemicals at room and medium temperatures, and does not undergo chemical reactions with them, ensuring the stability of the coating in corrosive environments.

Silicon dioxide (SiO₂): Silicon dioxide, which accounts for 5%, acts as a "buffer" and "enhancer" in coatings. It can absorb the impact load on the coating, alleviate stress concentration, prevent the internal grains of the coating from loosening due to stress, and thereby enhance the overall mechanical impact resistance of the coating. Meanwhile, the presence of silicon dioxide helps to enhance the density of the coating, further optimizing its wear and corrosion resistance.

Titanium oxide (TiO ₂): Adding 3% titanium oxide significantly improves the toughness of the coating. Titanium oxide is uniformly dispersed in the coating structure as small particles. When the coating is subjected to external forces, these titanium oxide particles can prevent crack propagation, allowing the coating to maintain high hardness while having better flexibility, avoiding cracking due to excessive brittleness, and improving the reliability of the coating in complex stress environments.

Chromium oxide -5% silicon 3% titanium (Cr ₂ O ∝ -5% SiO ₂ -3% TiO ₂) powder provides basic wear resistance and corrosion resistance through chromium oxide, optimizes coating density and high temperature stability with silicon element, enhances toughness and impact resistance with titanium element, forming a composite coating with balanced performance, and plays a precise protective role in multiple key components in the industry.

Textile industry: protection of core components

The components of the textile industry, such as guide rollers, stretching rollers, and separation plates, are exposed to fiber friction, temperature fluctuations, and slight humidity for a long time. The surface is prone to scratches due to continuous wear, or the accuracy may decrease due to residual fiber corrosion. The high wear resistance of chromium oxide in this coating can effectively resist repeated friction of fibers, reduce roller surface wear, maintain surface smoothness, ensure smooth fiber transmission, and reduce wire breakage rate. The addition of silicon element improves the density of the coating (with lower porosity), which can block the penetration of slightly corrosive media such as water vapor and textile additives, and protect the substrate from corrosion; The toughness enhanced by 3% titanium element alleviates the thermal stress caused by temperature changes, avoids coating cracking due to cold and hot cycles, prolongs the maintenance cycle of textile components, and improves the stability of product processing quality.

Compressor and cylinder: screw and inner wall reinforcement

During high-speed operation, the compressor screw is subjected to severe friction and high-pressure gas impact between the tooth surfaces, and traditional coatings are prone to efficiency degradation due to wear or brittle cracking. This coating relies on the wear-resistant basis of chromium oxide to reduce screw friction loss and lower operating energy consumption; The optimized structure density of silicon element enhances the coating's resistance to gas erosion and reduces the erosion of the screw surface by high-pressure airflow. At the same time, the toughness enhanced by titanium element can buffer the impact load during operation, avoid coating peeling, and ensure the accuracy of screw transmission. For the inner wall of the cylinder, the low friction characteristics of the coating reduce sliding wear with the piston ring, and the dense structure blocks the erosion of water vapor and impurities in the compressed gas, extending the service life of the cylinder, reducing the risk of compressor leakage, and improving operating efficiency.

Pump equipment: sealing area protection

The sealing area of the pump is a key part to prevent medium leakage, and it needs to withstand medium corrosion, friction and wear, and pressure impact. The corrosion resistance of chromium oxide in this coating can resist the erosion of pump conveying media (such as water, oil, and slight acid-base solutions), and the increased density of silicon element further strengthens the sealing barrier, reducing the sealing failure caused by medium penetration. At the same time, the wear resistance of the coating reduces the friction loss between the seal and the shaft sleeve, while the toughness enhanced by titanium element alleviates the impact stress during the start stop process, avoids cracks on the sealing surface, ensures long-term stable operation of pump equipment, and reduces maintenance costs caused by leakage failures.

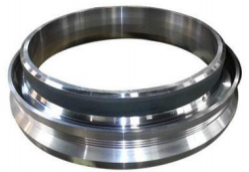

Mechanical engineering: Efficiency enhancement of shaft sleeves, plungers, and wear-resistant rings

The shaft sleeve, plunger, and wear-resistant ring in mechanical engineering are the core components that bear loads and reduce friction. They are prone to dimensional accuracy degradation or functional failure due to wear and impact. The high wear resistance of this coating can reduce the friction loss between the shaft sleeve and the shaft, and between the plunger and the cylinder body, thereby reducing the energy consumption of mechanical transmission; The structural stability optimized by silicon element enhances the deformation resistance of components under complex working conditions, ensuring dimensional accuracy. The toughness enhanced by titanium element enables the coating to absorb vibration and impact energy during operation, avoiding the problem of brittle fracture in traditional hard coatings and extending the service life of wear-resistant rings. In addition, the corrosion resistance of the coating can resist the erosion of impurities in lubricating oil, further improving the reliability of components, reducing equipment failure rates, and extending the overall service life.

In summary, the chromium oxide 5% silicon 3% titanium powder coating forms a balanced advantage in wear resistance, corrosion resistance, toughness, and density through multi-element synergistic optimization, accurately matching the performance requirements of components in the textile, compressor, pump, and mechanical engineering fields, providing reliable protection for efficient and stable operation of equipment.